Of course, don't take everything I say as gospel, this is simply some things I've learned throughout the years. No I'm no scientist, I'm no engineer and although I quite geek, I'm not a data monger. However if there's any information I feel is helpful, I'll put that up :)

Pressure versus Flow

When it comes to fuel systems, there are three functions that shape performance - Pressure, flow and voltage. Pressure and flow are going to be the main factors that we'll be looking at.

One thing that took me ages to get my head around is the simple physics of a fuel system all cars. Did you know that fuel pressure is at it's highest NOT when your engine is screaming and your turbo is at it's most boost-productive? Nope, your fuel pressure highest when your car is at idle.

Maybe many of you are thinking "well duh" but hey, it took me a good 20 minutes to get my head around this. Here's a simple parallel that helped me get it. Think of your fuel system as a closed circuit, like a garden hose. When at idle, your fuel pump is pushing fuel into a circuit that doesn't have a high output demand. Like the metaphorical garden hose set with a very small trickle at the end, the fluid within the circuit is under high pressure.

Under load however, things change. Under load is when your injectors are flowing at their highest.- like the garden hose that is open all the way. Although flow may be at its max, pressure in the line isn't as high when on idle.

This is where we find the line that divides a good fuel pump, from a great fuel pump. The job of the fuel pump is to supply fuel to the fuel rails, yes (duh). But in order to do this well, it must provide both flow volume AND pressure.

Imagine being a fuel pump sitting in a fuel tank. You essentially have two jobs. One job is to lift fuel up from the tank into the fuel circuit. The other job then is to keep this circuit pressurised so that fuel can flow through the injectors into cylinders. It may sound simple enough, but it's a tough job, especially if you're not a very big pump and especially if you've got big expectations on your shoulders.

Why fuel pumps fail

Here's a free one I learned from head tuner Chea from Powertune Australia. As a rule of thumb, every PSI of boost that comes through a turbocharged system demands one PSI of fuel pressure above base pressure.

So say base fuel pressure is at 40PSI. A turbocharged system at 36PSI boost will demand a whopping 76PSI from the circuit. Imagine being the poor fuel pump called to this kind of duty. You wouldn't last very long.

Most of the fuel pumps fails I've seen are attributed to wear on the internal motors. At anything over 60PSI fuel pressure and max flow, your fuel pump is really hitting the ends of itself and it's not going to be staying around. Other reasons why pumps fail is due to sucking up debris within the fuel which chews out the internal gears of the pump. For all the smaller fuel pumps, this is much more of a danger than the bulky ones like the Bosch (See below in the Comparo).

Back in the day of plain old octane tuning, there was no such thing as stupid amounts of boost. 24psi was about as high as you went which meant your fuel pump would be stretching to about 64PSI. However with the arrival of E85, previously unheard of boost pressures are now commonplace. This in turn has taken its toll on non-E85 ready fuel pumps.

One way to get around this is to have more than one pump like offered by this Powertune twin in-tank fuel pump kit. By doubling up on fuel pumps, you're essentially halving the job for each fuel pump. These kits are quiet in operation and don't take up any more room than the factory setup so are ultimate for the street-sleeper.

Another way to get enough fuel through smaller pumps is to run a surge tank setup. In a surge tank setup, one pump is designated as a lift-pump - lifting fuel into an external tank. A separate pump is (or series of pumps are) assigned purely to "push" the fuel from the external tank into the fuel rails. By not doubling up on duties, the pumps can be a lot more efficient at what they do. Surge tanks are bulky albeit effective.

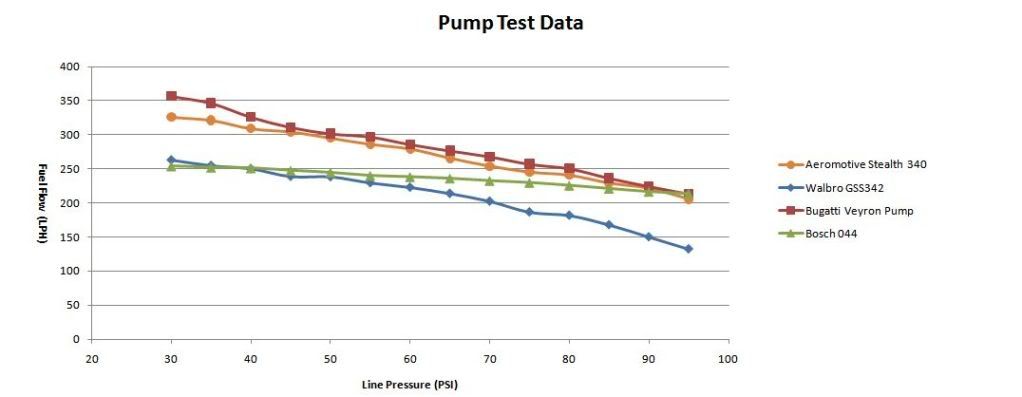

Not all fuel pumps are the same! (Duh). A particular pump may have amazing performance on idle, but absolutely suck under boost. Vice versa, some pumps might look a little shaky on idle and cause you to think "How on earth will this keep up with what I need" but then "POW!" when boost starts roaring, the pump arks up and puts on a show. Have a look at the graphs at the end of this write-up. In particular look at how the Bosch 044s compare to the Walbro. On idle, they're on par, but come the demand for fuel and the Bosch flogs ahead.

So key points to note about fuel pumps:

- It's not just about all about how much fuel they can move. A pump is judged on how much pressure it can create and handle.

- Although fuel pressure is highest on idle, fuel pumps work hardest under load as they struggle to flow, whilst maintaining high pressure.

- Multiple fuel pumps are a good idea.

- PSI of fuel pressure required on boost = PSI of base fuel pressure + PSI of boost

- Going with the above equation, E85 has put the pressure on fuel pumps.

A small comparo

Anyway, onto the comparo. Below is a list of some common fuel pumps you'll see in the market and some impressions I've picked up over the years in workshop circles. You'll note that they all hit their limits at about 350kWatw on 98RON and 320kWatw on E85. You might ask "If it's a better pump, shouldn't it make more power?". Short answer. No, better pumps just work better under demand.

Walbro 255lph - GSS341

This here has been the bread and butter of import tuning for the longest number of years. The Walbro 255 AKA "Walbro fuel pump" still is a hugely popular choice amongst car enthusiasts. Not so much amongst high level performance shops though I've noticed in recent times.

There've been many reports of this fuel pump not coping well under high boost applications. These will hit their limits at about 350kWatw on 98RON, and about 320kWatw on E85 but of course you don't want to be pushing your fuel pump to its limit for extended periods.

After all, if this guys chokes, then that's a potential catastrophic lean-out you have on your hands. You can pick these up for about $100 on eBay but watch out for fakes (yeah there are companies faking $100 items Д゚). This unit will replace a lot of factory fuel pumps.

Aeromotive 340lph - AER11142

This one is relatively new on the market but has left quite an impact. Experience reports it to responds to boost demands a lot more capable than the Walbro GSS341. I'm seeing a lot of workshops and customers switching over to this fuel pump especially when fuel-shortage on boost is an issue.Approximately $200 will land you one of these guys. Again like the Walbro, 320kWatw on E85 and 350kWatw on 98RON will take this guy to his farthest stretches, but remember, he has proven to to be a lot more reliable when big boost comes knocking.

Still though, we've seen some biggish (400rwkW) setups put twin sets of these guys out of action. Best kept to 98RON setups unless you're going to be doubling up.

Walbro 450lph - F90000267

These come in two designations, the F90000262 which is the Walbro 400lph fuel pump designed for petroleum-based fuel, and the F90000267 which is aimed for the E85 crowd. You can visually tell them apart by the presence of a plug. Electrical plug means it's the E85 designation. Just terminals means you have the 400lph version.

Although still new to the market at the time of this writing, the Walbro 450lph has already managed to claw its way to the top of the rat pack. It responds very well to boost and being an E85 fuel pump, was born for pushing at high flow-rates.

With big demand for ethanol tuning, we're sure see some promising numbers get pushed out by this bad boy. Stay tuned for more R&D numbers. One of these won't cost you much more than an Aeromotive Stealth fuel pump. $230 retail should score you one and the 450lph E85 pump will hopefully take me in excess of 350rwkW.

Bosch 044 or Bosch 040

What's the difference between the 044 and 040 I hear a lot of people ask? Simple answer is designation.

The Bosch 044 (pictured above as the bottom one) is an inline fuel pump. This means that you don't stick it in your fuel tank! These are best reserved as to simply do the "pushing" of fuel through your lines to your fuel rail. Just like above how we talked about surge tanks. This here is a push pump.

The Bosch 040 however, is an in-tank pump. For a system with an external surge tank or that features inline push pumps, it does the lifting. For a factory setup, it'll do both the lifting and the pushing.

Bosch is certainly a well-established name in this industry, however these pumps have been around for long time now and although are known for being sturdy and faithful, are a bit behind on the tech tree. They're physically larger and much of it's success may be attributed to this. They sport large, hearty motors that just keep going and going. Like an old bulldozer.

$200-$250 will land you one and they'll pump well for up to 350rwkW on 98RON albeit a little less on E85.

Deatschwerks

I have absolutely no idea about these guys. I recall back when I was working for Fast Fours and Rotaries magazine in 2010 seeing these guys being released into the market for the first time and thinking "Is it really German, or is that part of marketing?".

If they are German, they're definitely not German-priced (cheap as chips and so far seem to carry that stigma that's attached being a bit cheaper). I've come across these fuel pumps a number of times now but never in a large boosted setups - Mainly what Kenji would call "Stage zero modification" which generally means about the 200kWatw mark for am SR20 Silvia or Mitsubishi Evolution.

We all love graphs so here are some comparo graphs for you to stare at. Now I don't know whether or not these were created by researchers or by marketing managers so don't yell at me. It's here for your discernment.

|

| Have a look at so graphs at the end of this write-up in particular look at how the Bosch compares to the Walbro. On idle, they're on par, but come the demand for fuel and the Bosch flogs ahead. |

Before you go, please spare just a few seconds to provide some feedback on the below poll.

Helpfulness of article